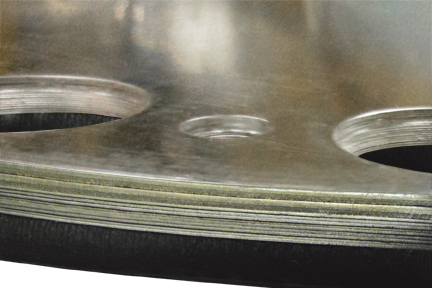

Edge Bonded Shims

The peelable layers of an Edge Bonded Shim set are first pressed together, and then adhered by only the edges of the Shim's profile. This allows for easy separation of the layers in the field. Since Edge Bonded Shims are easy to peel, the layers that are not needed are preserved and can be used for a later application. Edge Bonded Shim Sets have all the performance and cost advantages of solid and loose Shims, yet they provide a unique solution for companies seeking a better point-of-use adjustable Shim set.

>> Learn More about the Advantages of Using Edge Bonded Shims

Benefits of an Edge Bonded Shim Set

- Unused layers can be saved for later as no deformation occurs during peeling.

- Edge bonded shim sets have more versatility with size and shape, allowing any shape, design, large or small, to be manufactured.

- Edge bonded shim sets provide a more accurate and consistent preloading throughout the service life of the assembly without requiring a precise torque set.

- Materials used for edge-bonded shims are less expensive - along with reducing costs with reusable removed layers.

- Edge-bonded shim sets offer safe adjustment in seconds rather than time consuming and difficult to peel surface bonded laminates.

Edge Bonded Shims also provide cost saving advantages over Laminated Shims because the materials are less expensive. Edge Bonded Shim packs offer safe adjustment in seconds rather than time consuming and potentially difficult to peel surface bonded laminates. Safety improvement is realized because no knife is needed to remove the edge bonded layers. Cost savings can also be realized because removed layers are reusable, functional parts.

Click here to submit a Request for Quote

or call us today at 330.920.3655